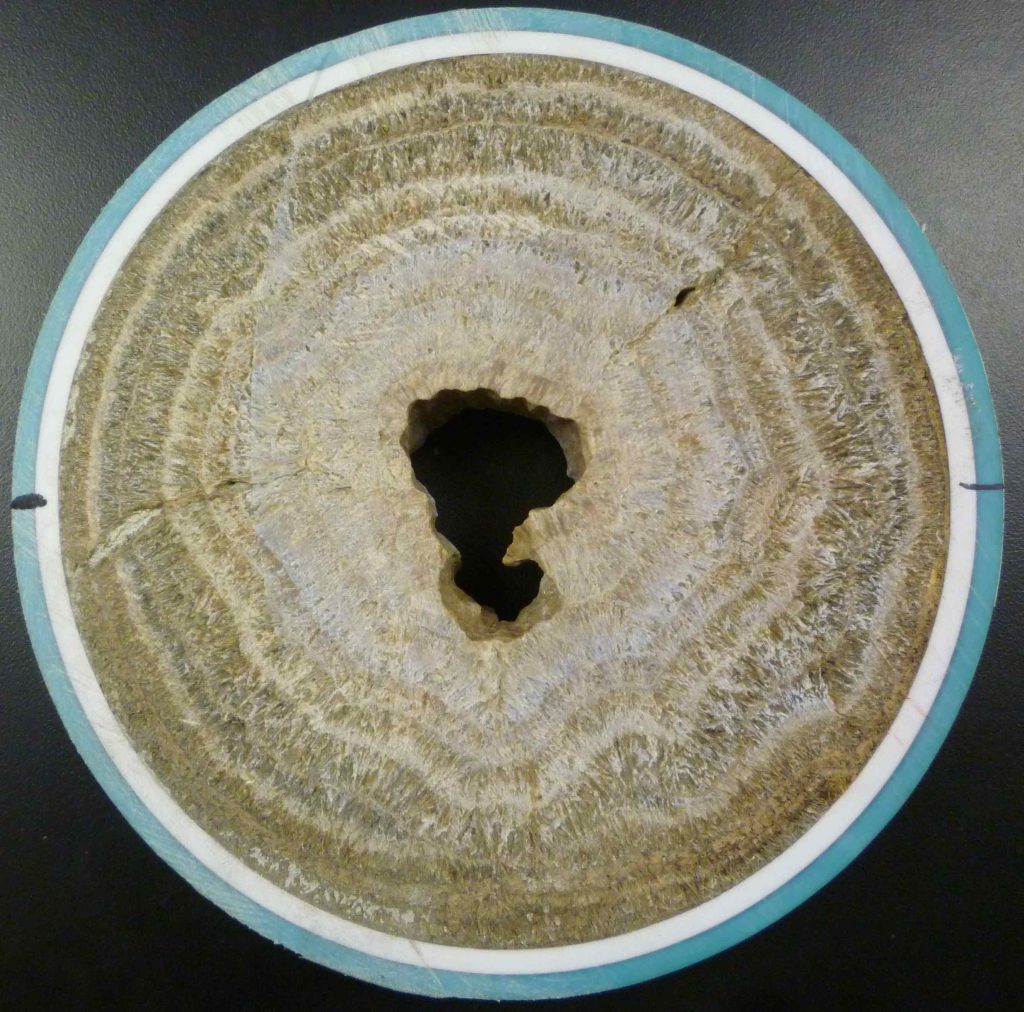

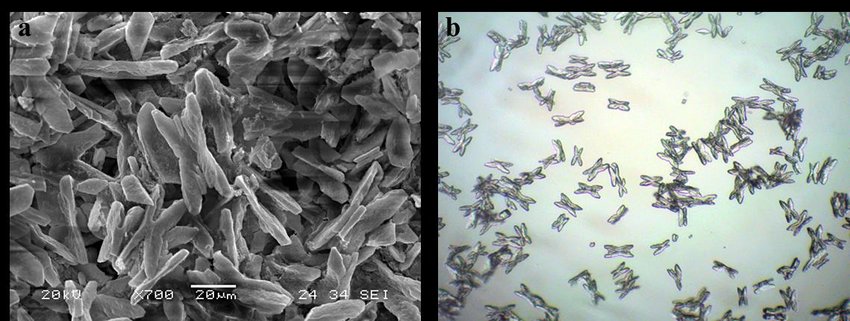

Magnesium ammonium phosphate, sometimes called struvite, is a grayish-white crystalline salt that builds up on the internal pump and piping surfaces used for lagoon liquid recycling. It usually appears on metallic surfaces but can also form on plastics. Steel, cast iron, bronze, and brass are equally susceptible.

Struvite usually builds up on the internal pump components first, then moves outward to the discharge pipes. It often occurs at pipe joints, elbows, valves, or imperfections because microscopic grit and solids tend to lodge at these points, providing a base for the salt to grow. Predicting struvite is difficult because its cause is not well known. Design, maintenance, and management techniques have been researched that can reduce the buildup to acceptable levels.

Pumping and Piping System

Use only high-quality, low-pressure, self-priming centrifugal or submersible pumps. They should not be oversized in relation to the piping network, and should perhaps be on a timer. The suction pipe should also be large enough to prevent pump cavitation. Normally the suction pipe diameter should be one size larger than the discharge pipe. Locate the pump close to the high-water level to minimize suction lift. Replace fine mesh suction intake strainers with wire screens or baskets of 1-inch mesh or larger. The diameter should be at least five times the diameter of the suction pipe. Struvite will also build up on the screens.

Use nonmetallic pipes and fittings. Pipes should be large enough to maintain flow velocities between 3 and 5 feet per second; the minimum pipe diameter at any point except at the immediate discharge point should be 1.5 inches. Sharp pipe bends (elbows and tees) should be avoided. Instead, use flexible plastic pipe and long sweep elbows for the direction changes. The system (pumps and piping) should have sufficient capacity to work only one-half to two-thirds of the time, and piping systems not in continuous use should be drained between pumping events.

Electrostatic Charges

Stray voltage is also believed to contribute to struvite. Direct grounding of the pump housing can discharge any static charges. A metal rod should be placed 10 to 12 feet into the moist soil near the lagoon’s edge, and cable connections at the ground rod and pump should be checked periodically for corrosion.

Lagoon Management

Lagoons should be properly sized. New ones should be charged at least half full of water before startup, and the liquid level should be brought up to design levels as soon as possible. Rainfall during normal years dilutes lagoon liquid while extended periods of hot, dry weather increase nutrient and salt levels and the rate of salt buildup in recycling systems. Flushing with fresh water or irrigating with a portion of the lagoon contents may help.

Acid Cleaning

Salts can be dissolved with dilute acid treatments. Several doses followed by flushing the spent acid solutions will be needed to treat heavy buildups. A more thorough and more costly method is to install an acid recirculation loop. Use a 150-gallon acid-resistant tank as the reservoir. You will need enough solution to fill the pipe length and some in reserve to keep the recirculation pump primed. Use the accompanying table to determine how much acid you will need.

Table 1. Amount of solution needed for acid cleaning using an acid recirculation loop.

| DIAMETER OF PIPE (INCHES) | SOLUTION NEEDED PER FT OF LENGTH (GALLONS) |

|---|---|

| 1.0 | 0.06 |

| 1.5 | 0.13 |

| 2.0 | 0.20 |

| 2.5 | 0.29 |

| 3.0 | 0.43 |

| 4.0 | 0.70 |

| 6.0 | 1.53 |

To reduce the size of the tank, isolate sections of the line with valves and circulate the acid through only one section. The flush pump suction is switched from the lagoon and connected to the bottom of the acid tank with a quick-connect coupling. A 1-inch line returns acid from the end of each treated pipe section to the tank.

Hydrochloric acid can be purchased at most chemical supply houses or paint stores. Dilute the acid with water on a 1 to 9 ratio — 1 gallon acid to 9 gallons of water. Use caution. Mixing acids with water is a hazardous operation. Partially fill the tank with water, then add the acid slowly to the water. Eye protection is essential, and heat will be generated. To treat heavy struvite buildups, recirculate the mixture overnight and count on using the mixture only once. Spent acid may be dumped into the lagoon.

References

Barker, J.C. 1981. Crystalline (Salt) Formation in Wastewater Recycling Systems. EBAE 082-81. North Carolina Agricultural Extension Service, North Carolina State University, Raleigh.

Payne, V.W.E. 1993. Personal Communication. U.S. Department of Agriculture, Soil Conservation Service, Auburn, AL.