Composting poultry mortalities is a relatively new, practical, and sanitary alternative to burial pits and incinerators. It is an economical, fairly odorless, and biologically sound practice for broiler, turkey, layer, and Cornish hen operations. Management commitment is the key to successful composting.

Composting resolves the disposal problem and yields a valuable product — a reduced odor, spongy, humus-like material that has several marketable uses ranging from soil conditioner to horticultural growing medium. Some states may require that composted birds be applied to the grower’s own land; even so, composting has other values:

- Composting is environmentally sound; properly done, it decreases the potential for surface and groundwater contamination.

- Composting destroys disease-causing organisms and fly larvae.

- The materials needed for composting — mortalities, litter, and sometimes straw and water — are readily available on the farm.

- Once a composting system has been set up, it will not require much labor.

- Compared to other options, composting is a less costly method of mortality processing.

A Natural Process

Composting is a controlled, natural aerobic process that decomposes organic waste, changing it into a stable product. Decomposition is driven by heat, bacteria, and fungi fueled by carbon, nitrogen, oxygen, and moisture.

The grower’s tasks are to collect the carcasses and place them in alternating layers with the manure and straw (or other carbon sources), and to monitor the process to ensure that enough heat is being generated to complete the process of decomposition. The grower will also turn the composting mixture, usually by moving it from one bin into another. Turning the compost ensures that the entire mass is sufficiently aerated.

Composter Design and Operation

Composting poultry mortalities can be done in or outside the poultry house, but it should always be done in an environmentally safe and healthy manner, under a roof, and protected from rain, stormwater, or surface water flow. Most poultry mortalities will be composted in a facility housing a two-stage large bin composter designed as follows:

- The size of the primary bins is determined by the following equation:

- V = flock size x (rate of mortality/total number of days) x average market weight x 2.5 cubic feet

- The secondary bins should equal the primary bins since experience teaches that one cubic foot of primary bin and one cubic foot of secondary bin are needed per pound of daily mortality.

- The height of bins should not exceed 5 feet. Heights greater than 5 feet increase compaction and the potential for overheating.

- The width of the bins is usually selected to accommodate the loading equipment. A width of 8 to 10 feet is normal, but the bins could be wider.

- The depth of large bins is not restricted, assuming that the operator has appropriate mechanized equipment to manipulate the compost from front to back. Deeper bins are more difficult to enter and exit and take more time to work. Secondary bins can be larger, but they must have the same capacity as the primary bins (see Fig. 1).

- Extra primary bins will provide useful storage for litter and straw. If high mortalities occur, these bins could be used for composting.

- The ceiling height of the composter should be high enough to accommodate a front-end loader extended upward.

Location and Access

The decision to use a composting system for poultry mortality management means that the grower is committed to managing the composter facility properly and seeking help as needed. Once the composter bins have been adequately designed, the building itself should be considered. A few general principles apply to the composting facility.

Foundations

An impervious, weight-bearing foundation or floor, preferably of concrete, should be provided under primary and secondary composting bins. Experience has shown that after frequent loading and unloading activities, dirt or gravel tends to become rutted and pot-holed. A good foundation ensures all-weather operation, helps secure against rodent and animal activity, and minimizes the potential for pollution of surrounding areas.

Building Materials and Design

Pressure-treated lumber or other rot-resistant materials are necessary. A roofed composter ensures year-round, all-weather operation, helps control stormwater runoff, and preserves composting ingredients. Adequate roof height is also needed for clearance when using a front-end loader. The amount of rain that is

Composting Recipe and Method

Table 1. Typical Recipe for Composting Dead Birds

| Ingredients | Parts By Volume |

|---|---|

| Dead Birds | 1 |

| Litter | 1.5 |

| Straw | 0.5 – 0.75 |

| Water | 0.0 – 0.5 |

Water May not be necessary. Too Much water can result in anaerobic conditions. An alternative recipe uses 1 part birds with 2 to 3 parts of litter cake (i.e. litter having a high moisture content)

Water may not be necessary. Too much water can result in anaerobic conditions. An alternative recipe uses 1 part birds with 2 to 3 parts of litter cake (i.e. litter having a high moisture content)

For composting poultry mortalities in a two-stage composter, a prescribed mixture of ingredients is used called a “recipe.” The recipe calls for dead birds, litter, straw or other carbon source, and water (Table 1). Recipes for a single-stage composter differ slightly.

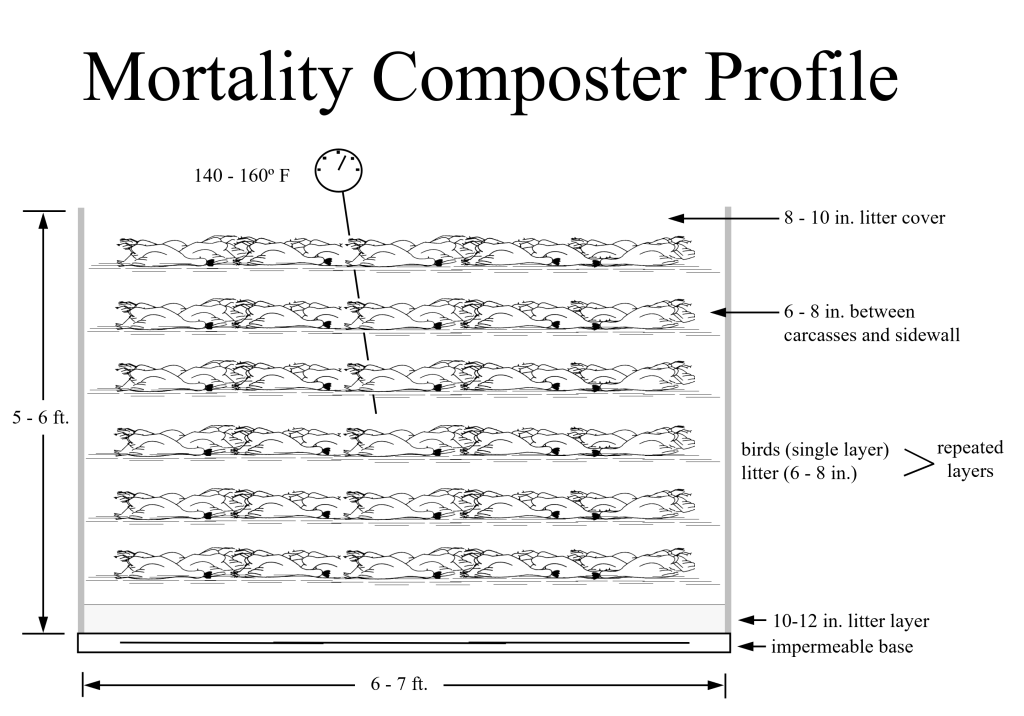

Proper layering of the recipe will ensure appropriate heat (from microbiological activity) for composting the mortalities in about 14 days. To begin, place 10 to 12 inches of litter or manure as a base, followed by a layer of dead birds. Depending on the moisture content of the manure or cake, water may or may not be added. Alternate layers of litter (6 to 8 in.) and mortality, repeating this process until the pile or bin is full (see Fig. 2).

Leave 6 to 8 inches of space between the edges of the dead bird layer and the wooden wall of the composter. This space allows air movement around the pile and keeps carcasses nearer to the center of the pile, where the heat is highest. Do not stack dead birds on top of each other. They may be adjacent to one another, even touching, but they must be arranged in a single layer. Spread litter or manure and straw as evenly as possible.

Use the same layering sequence (dead birds, litter, and straw) after loading mortalities that only partially complete a layer. If dead birds are carelessly loaded — stacked one on another or placed against the sidewalls of the structure — they will putrefy. Once the compost pile is complete, or full, “cap it off” with a 8 to 10-inch layer of dry litter, manure, straw, or similar material to reduce the potential for attracting flies and to provide a more pleasing appearance. This same recipe can be used for composting caged layers, broilers, turkeys, breeders, or other types of poultry.

Mixing, aerating, and moving the composting mass with a front-end loader or shovel will uniformly distribute the ingredients, add oxygen to the pile, and reinvigorate the composting process. Temperatures will rise after each mixing until most readily available organic material is consumed. After the pile is capped, wait 11 to 14 days before turning the mixture. However, if the temperature falls below 120°F or rises above 180°F, the compost pile should be aerated or mixed immediately.

Successful composting requires a specific range of particle sizes, moisture content, car- bon-to-nitrogen ratio, and temperature. The following general rules apply:

- Particle Size

- Particles that are too small will compact to such an extent that air movement into the pile is prevented. Material that is too large allows too much exchange of air, and so prevents the heat from building up properly. A proper mixture of size allows both air exchange and temperature buildup.

- Moisture Content

- The ideal moisture content in the composting pile ranges from 40 percent to 60 percent. Too much moisture can cause the pile to become saturated, which excludes oxygen. The process then becomes anaerobic, a condition that results in offensive odors and attracts flies. Runoff from a composter that is too wet can pollute the soil or water. Too little moisture reduces microbial activity and decreases the rate of composting.

- Carbon-to-Nitrogen Ratio

- Carbon and nitrogen are vital nutrients for the growth and reproduction of bacteria and fungi; therefore, the ratio of carbon to nitrogen (C:N) influences the rate at which the composting process proceeds. Conditions are most ideal for composting when the C:N ratio is be- tween 15:1 and 35:1.

- If the C:N is too high, the process slows down because it has insufficient nitrogen. This imbalance can be corrected by adding more manure or litter to the compost pile. If the C:N ratio is too low, the bacteria and fungi cannot use all of the available nitrogen, and the excess nitrogen will be converted to ammonia, resulting in unpleasant odors. This problem is fixed by adding more straw or sawdust.

- More recent experience has shown, however, that composting poultry mortalities results in a partial compost. Hence, maintaining the exact carbon-to-nitrogen ratio, while important, is not critical. Many recipes now reduce or eliminate straw entirely, substituting cake, as previously noted, or even the composted product. In fact, 50 percent of the contents in the secondary bin can be input with a new batch of mortalities in the primary bin. This practice reduces the amount of compost that will need to be land applied by 50 percent.

- Temperature

- The best indicator of proper biological activity in the composter is temperature. Use a probe-type 36-inch stainless steel thermometer, 0 to 250°F, with a pointed tip to monitor temperatures within the compost pile. The optimum temperature range is 130 to 150°F. When the temperature decreases, the general problem is that not enough oxygen is available for the bacteria and fungi. Oxygen can be replenished by turning or aerating the pile. Temperatures will rise as the composting process repeats itself.

- The cycle of composting, turning, and composting can be repeated as long as there is organic material available to compost and the proper moisture content and C:N ratio are present. When temperatures reach the optimum range for three days, harmful microorganisms (pathogens) and fly larvae will be de- stroyed. Daily recording of the temperatures in the piles is important because it will indicate whether the bacteria and fungi are working properly.

Small Bin Composting Systems

Small bin composters are two-stage composters developed for use on farms with limited equipment. The size of the primary bins is limited, primarily by the reach of the loader; so how many bins there will be is determined by how many are needed to dispose adequately of the mortalities. The secondary bins must be equal in capacity to the primary bins, but may be fewer in number than the primary bins and larger — they may be, and often are, twice the volume of the primary bins.

Recall the equation (in PMM / 2) for determining the size of the bins in the large bin composter:

- V = flock size x (rate of mortality/total number of days) x average market weight x 2.5 cubic feet

The same equation can be used to size the small bins. Growers using limited equipment will probably want to build smaller bins. That is, they will build as many small bins — each about 5′ x5′ x 8′ — as they need to reach the required volume.

Table 2 illustrates this equation. It shows the number of primary bins that broiler growers will need depending on the size of their flock, the birds’ weight, and the volume in the bin for flocks ranging from 20,000 to 200,000 broilers.

| No. of Broilers | Lbs. Dead/Day On Day 50 in lbs. | Volume in 1st stage2 in CF | No. of bins in 1st Stage |

|---|---|---|---|

| 20,000 | 67 | 168 | 2 |

| 40,000 | 134 | 335 | 2 |

| 60,000 | 201 | 503 | 3 |

| 80,000 | 268 | 670 | 4 |

| 100,000 | 335 | 838 | 4 |

| 120,000 | 402 | 1,005 | 5 |

| 140,000 | 469 | 1,173 | 6 |

| 160,000 | 536 | 1,340 | 7 |

| 180,000 | 603 | 1,508 | 8 |

| 200,000 | 670 | 1,675 | 8 |

- lbs. Dead/Day on Day 50 assumes mature weight of 4.2 lbs; flock loss of 4% or 0.8 bird/day/1000.

- Volume in 1st stage in CF (Total weight loss near maturity) x (2.5 cf/lb dead weight) = volume storage required.

Forced Air Composting

Forced air composting is similar to static bin composting except it has a series of perforated pipes designed into the concrete floor of the composter. A fan or air compressor is attached to the perforated piping system creating a negative or positive pressure thus forcing air into or through the compost mix. It also has a leachate collection basin; the leachate can be recycled through the compost mix. The system is designed to keep the mix aerated, thus keeping sufficient oxygen on the compost mix at all times.

Drum Composting

Another method to compost is the drum method. Dead birds and carbon materials are loaded daily. The drum turns a revolution or two and the compost mix decomposes by “slow cooking.”

Based on the manufacturers’ design time the compost mix will stay in the drum five to eight days. As the drum is rotated each day the compost mix will advance to a discharge point and be discharged. The compost mix being discharged is a green compost and will need additional composting time if a finished product is desired.

Composting Catastrophic Mortalities

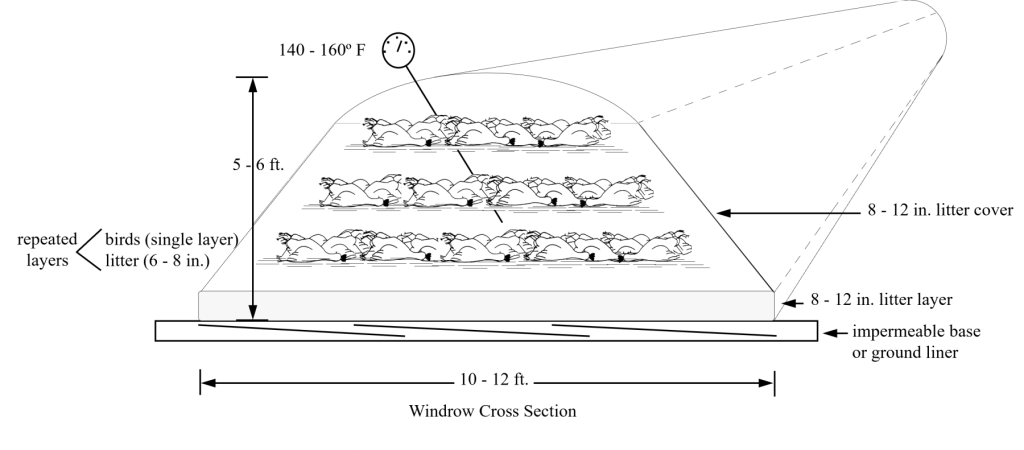

Composting large numbers of poultry mortalities after a catastrophic event is relatively simple and inexpensive, and should be considered over burial for water quality protection. The process is the same as for normal mortality numbers, but without the bins.

Catastrophic mortality can be composted in the bedding or litter where the poultry were housed if the whole population is involved and adequate space and time are available, or they can be composted outside. If a disease such as Avian Influenza has depopulated the flock, in-house composting is strongly recommended because this will keep the virus from spreading. Prior planning is necessary to ensure that the materials needed to build the composting pile or windrow (especially the bulking agent, sawdust, wood chips, or straw) will be on hand.

When composting catastrophic mortalities in a windrow, allow at least one cubic foot of bulking material per 10 pounds of expected mortality (e.g., 1,000 birds at three pounds each would re- quire 300 cubic feet of bulking material); and size the windrow according to need. A window 12 feet wide by 6 feet high by 1 foot long will hold ap- proximately 300 pounds of mortality. Thus, 1,000 birds at 3 pounds each would require a windrow 3 feet long with appropriate end cover; and the materials needed per cubic foot of windrow length (300 pounds of mortality) would be 400 pounds of litter and 700 pounds of sawdust or another bulking agent.

Nine steps must be taken to build a windrow outside:

- Select a well-drained site;

- Make a bed layer of wood chips 12 inches thick and 12 feet wide for the length of the windrow;

- Add a 4-inch layer of fluffed straw as a base;

- Deposit an 8- to 10-inch layer of mortalities, but stop about a foot from the edge of the lower layer;

- Spray the mortalities with enough water to saturate the feathers;

- Deposit a 6-inch layer of sawdust or another bulking agent to the width of the birds; and

- Repeat Steps 3 to 6 as needed. Then,

- Starting from the bottom, cover the entire pile with a layer of sawdust, 6 to 8 inches thick; and

- Add to the length of the windrow as more birds die.

If building the windrow inside, repeat steps 4 to 6 two more times or until the pile is 6 feet high. If the height of the poultry house prevents a 6-foot-high window, make only two layers (approximately 4 feet high). This will increase the windrow length requirement by approximately one-third.

| Depth of Litter (Inches) | Volume of Litter (Cu. Ft.) | Volume of Sawdust/Litter Required (Cu. Ft.) | Volume of Sawdust Needed (Cu. Ft.) | Volume of Water Needed (Gallons) |

|---|---|---|---|---|

| 2 | 3,340 | 13,000 | 9,660 | 12,500 |

| 4 | 6,600 | 13,000 | 6,340 | 12,500 |

| 6 | 10,00 | 13,000 | 3,000 | 12,500 |

| 8 | 13,400 | 13,000 | 0 | 12,500 |

| 10 | 16,660 | 13,000 | 0 | 12,500 |

- Estimated material requirements for 25,000 birds at 5 pounds per bird in a 40¢ x 500¢ house. (Note: The amounts of sawdust/litter and water needed are proportional to the bird weight, i.e., a 2.5 lb. bird will require approximately half the litter and water requirement.)

- Based on estimated 1/2 gallon volume of water needed to wet one bird (volume may be more or less; feathers must be thoroughly wet but be sure not to saturate the sawdust/litter mix).

To inactivate pathogens in the litter, use all the litter in the house in the composting process.

To maintain the windrow:

- Use a long-stemmed thermometer to ensure that the temperature is rising — it should reach 135 to 145°F within a week

- As the temperature declines (after 7 to 10 days) to 115 to 125°F, turn the windrow;

- In turning the material, be sure to lift and drop it in place (rather than merely pushing it) to form a new windrow;

- Add water if the material is too dry (does not leave your hand moist when squeezed), or sawdust, if it is too moist (drips more than two drops in your hand); and

- Cover any exposed carcass tissue in the new windrow with more sawdust.

After an additional three or four weeks the compost can be added to manure in storage for land application.

Because the poultry industry is so often concentrated in a geographic region, there can be many opportunities for recycling the by-products of production, including normal and catastrophic event mortalities. Composting normal and catastrophic poultry mortality on the farm can save transportation fees and tipping costs, reduce the potential spread of pathogenic diseases, and prevent groundwater pollution from burial practices.

Financial Considerations

Costs of composters depend on many factors — size, configuration (e.g., work areas, ingredients, and finished compost storage), and utilities. Some composting structures have been built for as little as $500; others, for as much as $50,000. No specific plan or layout for composters works best in all cases. Many different designs will per- form adequately, but management capabilities determine the success of the composting process. Standard plans and management information for poultry mortality composters are available through local USDA Natural Resources Conservation Service or Cooperative Extension Service offices.

Financial aid or cost-share funding may be available to help pay for the design and construction of composting facilities. Check with your local conservation district, USDA Natural Resources Conservation Service, or Cooperative Extension Service offices to learn more about these programs.

Changes in the recipe and design of composters are an indication that this practice is still in development, and further refinements can be expected. In the meantime, the composter de- signs now available can be used not only to deal with routine mortalities, but also for catastrophic losses. Growers interested in using this mortality management approach are urged to contact the appropriate local, state, and federal agencies for assistance.

Composting Compared to Other Disposal Practices

An emerging technology in the early 1990s, composting is now a preferred method of mortality management. It protects the environment and animal and human health, and it does not have quite the risk of air pollution that incineration does. In addition, composting can be scaled up or down in size, with corresponding differences in the grower’s costs. Most comparisons between composting and other disposal methods use the price of the two-stage composter as the base composter cost. In fact, minicomposters can be built for a third or less of that cost.

References

Arkansas Soil and Water Conservation Commission and the Water Resources Center. No date. Composting: A Safe and Simple Alternative in Water Quality and Poul- try Disposal Pits. Fact Sheet 2. Arkansas Soil and Water Conservation Commission, Little Rock.

Brodie, H.L. and L.E. Carr. 1998. Composting Animal Mortalities on the Farm. Fact Sheet 717. Cooperative Extension Service University of Maryland, College Park and University of Maryland Eastern Shore.

Brown, W.R. 1993. Composting Poultry Mortality. Presentation. Poultry Waste Management and Water Quality Workshop. Southeastern Poultry and Egg Association, Atlanta, GA.

Carr, L.E. et al. 1998. Composting Catastrophic Event Poultry Mortalities. Fact sheet 723. Maryland Cooperative Extension Service, University of Maryland, College Park.

Commercial Composting. Piedmont Conservation Council, Inc. 116 E. Pine Street, Graham, NC.

Donald, J.O., C. Mitchell, and V.W.E. Payne. No date. Poultry Waste Management and Environmental Protection Manual. Circular ANR 558. Cooperative Extension Service, Auburn University, Auburn, AL.

Donald, J.O., C. Miller, and V.W.E. Payne. 1996. Poultry Waste Management and Environmental Protection Manual. Circular ANR 558. Cooperative Extension Service, Auburn University, Auburn, AL.

Fulhage, C. 1992. Composting Poultry Carcasses in Missouri. WQ205. Cooperative Extension, University of Missouri, Columbia.

Hammond, C. 1994. Poultry Composting Facilities. Cooperative Extension Service and University of Georgia College of Agriculture and Environmental Sciences. In cooperation with the Tennessee Valley Authority. Uni- versity of Georgia, Athens.

Murphy, D.W. 1993. Minicomposter — Dead Bird Disposal. Fact Sheet 642. Cooperative Extension, University of Maryland, College Park.

Murphy, D.W. and L.E. Carr. 1991 rev. Composting Dead Birds. Fact Sheet 537. Cooperative Extension, University of Maryland, College Park.

Scarborough, J.N., D.H. Palmer, and T.H. Williams. No date. Composting Structures for Dead Poultry. Delaware Cooperative Extension, University of Delaware, Newark.

Tablante, N.L., L. Carr, and G. Malone. 2002. Guidelines for In-house Composting of Catastrophic Poultry Mortality. Fact Sheet 801. Maryland Cooperative Extension, University of Maryland College Park-Eastern Shore.

U.S. Department of Agriculture. 1993. Agricultural Waste Management Handbook, Part 651. Soil Conservation Service, Washington, DC.

Warren, K. 2000. A Forced Aeration Composting Bin System Designed Specifically for Poultry Growers. Mountain Organic Materials, Candler, NC.