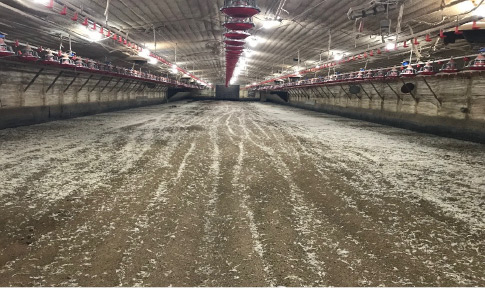

One of the most important aspects of commercial poultry production today is the effective management of litter material. Litter management practices will become even more critical as much of the broiler industry moves toward antibiotic-free production to meet consumer demand. Poor quality litter can have serious negative consequences on bird health and overall flock performance. Litter plays an important role in managing the moisture level within the broiler house. The litter acts as a huge sponge by absorbing large amounts of moisture and diluting the fecal material. However, depending on management programs, litter can become overwhelmed by the amount of moisture in the house, resulting in wet or caked litter.

Wet or caked litter tends to be at risk for higher ammonia levels, increased incidence of footpad dermatitis, and increased numbers of pathogenic organisms such as bacteria, molds, viruses, coccidia, and intestinal worms. Having proper litter depth, which appears to be around three to six inches for optimal bird performance, will allow for greater water retention and will help pull water away from the surface of the litter where it is in contact with the birds. Litter should be able to absorb a lot of moisture from within the broiler house but should also have a quick drying time to get rid of the moisture it absorbs.

Emphasis on Paw Quality

Wet litter is likely the major contributing factor affecting condemned chicken paws due to footpad dermatitis issues. Chicken paw prices have skyrocketed in recent years due to an increased demand for high quality paws to export overseas. Prior to the mid-1980s, paws were of little economic value and were rendered along with the rest of the offal including blood, feathers, and the other unsaleable parts of the broiler. Things have changed dramatically since then, however, to the point that paws are now the third most important economic part of broiler chickens behind the breast and wings.

Paw quality is also used today as an assessment of bird welfare. Footpad dermatitis not only costs the poultry industry millions of dollars each year in lost revenue, it is also currently used as an indicator of welfare practices in animal welfare audits. Therefore, the emphasis today on improving foot health and reducing the incidence of footpad dermatitis offers the opportunity for dual benefits that include: 1) increased profit from a greater number of exportable paws, and 2) having management practices in place that allow the poultry industry to meet current animal welfare standards.

There are benefits to recycled litter where paw quality is concerned. Paw quality seems to be better on built up litter that is well maintained and has a proper moisture content than on new bedding or even second or third flock litter. New bedding that may be of inadequate depth, inferior quality, or contain large chunks or sharp edges does not lend itself well to maintaining acceptable paw quality. After a year or more of growing flocks on new bedding, the litter is deeper and softer, with fewer sharp edges, and paw quality improves if the litter remains dry. Therefore, even though there are challenges associated with reusing litter such as the potential for increased ammonia and pathogen levels, there are also benefits such as improved paw quality and cost savings from not having to purchase new bedding materials (which may be expensive and difficult or perhaps impossible to secure) quite as often.

Litter Management

Most bedding materials used by the poultry industry have become more expensive in recent years as competing markets offer more for the materials than is feasible for the poultry industry. This increased demand from competing markets may also mean a shortage of available material even if the price is favorable to the poultry industry. As a result, this may lead to situations where inadequate amounts of bedding materials are placed in broiler houses. In addition, spreader trucks may not uniformly spread bedding material resulting in material being thicker in the middle of the house and much thinner near the walls. Often times this will result in litter slicking over near the walls because the material is not deep enough at the walls to handle the moisture load in the house. It is critical that the litter is evenly spread throughout the house, end-to-end and side-to-side.

The goal of litter management is to ensure that litter stays dry and friable throughout the flock. Two of the most common challenges to keeping litter dry are inadequate ventilation (especially during cold weather) and poorly managed drinker lines. Houses where the drinker lines are adjusted too low or have the water pressure adjusted too high will almost always have wetter floors. In addition, water supplies that carry a high particulate load or water lines that may have issues with biofilm growth will often times cause nipples to leak, increasing litter moisture. Frequent flushing and sanitizing the drinker and supply system may help reduce water wastage due to leaking nipples. Feeder and drinker lines are high-traffic areas and it is critical to maintain dry litter in these areas to improve litter quality which, in turn, will improve paw quality, lessen the risk of hock burns and breast blisters, and maintain a better welfare environment. Increased water excretion can result from health issues such as necrotic enteritis or from other factors such as medications used to treat disease, nutritional imbalances, and certain feed ingredients. All these situations will challenge growers in their efforts to keep litter dry.

Inadequate ventilation also challenges growers and greatly reduces the chance that litter will remain dry and friable. Growers may reduce ventilation rates during cold weather to save on gas usage. However, as a result, the litter is soon overwhelmed by the increased moisture load in the house and begins to slick over and form cake. Relative humidity levels of greater than 70% for any extended length of time will result in wet litter. Once the litter has gotten wet, it will take a lot more heat to dry it back out than it would have taken to maintain it with adequate ventilation in the first place.

Fuel usage and cost are required to maintain optimal litter conditions early in the flock during cold weather. During cold weather, whenever minimum ventilation fans run on their time cycle, the brooders will generally come on shortly thereafter. Brooders running will increase the fuel cost and growers may be tempted to reduce the minimum ventilation rate but this should not be attempted. Moisture, CO2, and ammonia levels quickly rise in an under-ventilated house, rapidly deteriorating the house environment and litter quality. However, by providing adequate ventilation and maintaining good litter quality, much of the fuel cost can be recaptured through improved bird performance throughout the flock.

Litter Treatments

Acidifiers are the most commonly used litter treatments. Acidifiers convert ammonia to ammonium. Unlike ammonia, ammonium does not easily convert to the gaseous form and tends to remain bound in the litter. Acidifiers also reduce the pH of the litter generally from 7.0 down to around 4.0, thereby creating a hostile environment that inhibits the growth of ammonia producing bacteria and other potentially harmful bacteria such as Clostridia, Salmonella, and E. coli. Acidifiers generally have a short lifespan in the broiler house; usually two weeks or less. However, they do a good job during the early brooding period at keeping ammonia levels in check and helping to minimize fuel use.

The most common dry acidifiers are sodium bisulfate, aluminum sulfate and sulfuric acid clay. A combination of sulfuric acid and aluminum sulfate is a common liquid acidifier. Sodium bisulfate is a dry acid salt that is activated by moisture in the environment. It lowers litter pH, thus reducing ammonia, and the sodium component helps to reduce litter pathogen levels. Ammonia is bound by the sulfate, preventing it from being released as a gas. Sodium bisulfate works best when top dressed onto the litter close (within 24 hours) to bird placement.

Aluminum sulfate is similar to sodium bisulfate in that it is a dry acid salt but different in that the acid is produced through the reaction with water in the litter instead of environmental moisture. Aluminum sulfate has an added benefit in that it binds phosphorus, making it unavailable. The amount of litter moisture is critical if aluminum sulfate is used. Aluminum sulfate is most commonly top dressed onto litter three to seven days before chick placement, depending on litter conditions. Application time depends on level of litter moisture. Apply the product three to four days ahead of placement with “wet” litter (20-35% moisture) and six to seven days ahead of placement with “dry” litter (<20% moisture).

Sulfuric acid is commonly incorporated into a clay bead that looks similar to kitty litter for ease of application and safety purposes. Sulfuric acid is a very strong acid and does not require moisture for activation. Similar to sodium bisulfate and aluminum sulfate, ammonia is converted to ammonium and bound to sulfate. Application works best one to three days before chick placement.

The liquid combination of aluminum sulfate and sulfuric acid is sprayed on the litter two to three days prior to chick placement. It must be allowed to form a “crust” for 24 hours to be effective. You should not walk on or disturb the litter while the “crust” is forming. It must be applied by a licensed applicator. Growers may purchase and apply the dry products themselves, but it requires a license and special equipment to handle this product.

Odor and Moisture Concerns

Broilers in the U.S. are raised in houses with earthen floors on litter material (often reused multiple times) composed of an initial bedding material (pine shavings, rice hulls, peanut hulls, etc.) mixed with feathers, spilled feed, water, and manure. In general, litter is a loose, friable, absorbent material on the floor of broiler houses used to provide thermal insulation, absorb moisture, provide cushioning from the earthen floor, and allow birds to demonstrate certain natural behaviors such as dust bathing and scratching (Collett, 2012; Shepherd and Fairchild, 2010). Good quality litter should also readily give up moisture and offer a reasonably quick drying time (Bilgili et al., 2009; Grimes et al., 2002) and should have a dedicated use after removal from the broiler house (fertilizer, soil amendment, etc.).

Often, in congested locations near feeders, drinkers, and/or exhaust fans, a compacted layer with a high moisture content (≥40 percent), referred to as “cake” (Miles et al., 2008), forms over the litter surface. Management practices should focus on preventing/limiting cake formation, as it creates issues with wet litter, ammonia (NH3) production, and increased bacterial load in the house. Both loose, friable litter and wet cake are potential fertilizer sources for row crops or hayfields/pastureland once removed from the broiler house. However, with today’s increased attention on the environment, the conversion of nitrogen (N) compounds in manure to NH3 is a source of environmental concern. Furthermore, lack of homogeneity (dry litter vs. cake) creates difficulty in accurately estimating NH3 volatilization from the litter surface, even though fundamental relationships among litter, pH, moisture, and uric acid N are well known (Gates et al., 1997).

Odor

Odor is a natural part of broiler production resulting from aerobic and anaerobic microbial activity in the litter (Pillai et al., 2012). Unfortunately, odor from litter in broiler housing has, at times, led to nuisance complaints. Complaints continue as many former urban dwellers move to the country, and subdivisions spring up adjacent to existing poultry farms. Odor itself is a complex mixture of odorous ingredients composed of volatile organic compounds (VOCs) and non-VOCs such as NH3, hydrogen sulfide, and other compounds. There are a variety of odorous compounds released during decomposition of organic matter, making litter the primary source of odor from broiler houses. However, conditions within the litter will influence formation and emission of odor that result in changes to concentration and character of odor exhausted from broiler houses (Wadud et al., 2012).

Broilers deposit moisture-laden organic matter (manure) onto the litter surface and gradually mix it into the litter during their daily activities. Nutrients in manure are the catalyst for some odorant emissions, while other odorants are emitted directly from the manure (Dunlop et al., 2016a). Addition of nutrients to the litter fuels microbial decomposition processes that release these odorants (Mackie et al., 1998). In addition, the birds produce substantial amounts of heat (particularly as they near market weight) and warm the litter when they sit down. Microbial growth and diversity in litter are influenced by a variety of factors, including stocking density, original bedding material (pine shavings, rice or peanut hulls, etc.), pH, moisture content, and litter temperature. In addition, Woodbury et al. (2015) suggested frequent wetting and drying cycles might result in a more diverse microbial population compared to chronically wet conditions.

Daily bird activities such as scratching and dust bathing increase exposure of emission sources at the litter surface, which may result in higher emission rates from those sources (Dunlop et al., 2016a). The birds themselves also have a large impact on odor emissions. Trabue et al. (2010) reported that presence of birds in a house corresponded with a seven-fold higher level of VOCs compared to the same facility without birds. These researchers indicated that this demonstrated the importance of characterizing odor emissions from facilities while birds are present because there were distinct differences in both odorant diversity and concentrations with or without birds on the farm. This is in part because presence of birds affects airspeed and turbulence at the litter surface, which may affect evaporation and emission rates.

Miles et al. (2008) indicated that larger birds better insulate the litter surface toward the middle and end of the flock, thereby restricting airflow across the litter, which may be more influential on litter gas flux than seasonal conditions. However, seasonal changes in temperature require complementary ventilation adjustments to help birds maintain the appropriate body temperature. Elliott and Collins (1982) reported that 1-2° C increases in house temperature can greatly increase NH3 volatilization. Gates et al. (1997) reported ventilation rate controls litter moisture, and winter ventilation rates are often less than in other seasons as growers reduce ventilation in an attempt to lessen heating costs. However, decreased winter ventilation leads to increased litter moisture and NH3 levels that can threaten flock health and performance. Often, increased ventilation rates are required to maintain acceptable NH3 levels within houses. In addition, these rates are generally higher than rates required for moisture removal alone (Xin et al., 1996). Even though odor is a natural part of broiler production, keeping litter at or near 25 percent moisture content will lessen generation of odor and emission of ammonia.

Moisture

Moisture is a key factor influencing litter quality in broiler houses (Tabler et al., 2012). The higher the moisture content, the longer bacteria can survive in litter. For example, in dry litter, bacteria may only survive a few hours or days, while in wet litter, survival may extend up to several weeks. In addition, wet litter is associated with a variety of concerns such as lost performance, animal welfare, flock health, food safety, and environmental impacts (Dunlop et al., 2016b). Wet litter is often related to poor drinker/ventilation management, disease outbreaks, and digestive issues (van der Hoeven-Hangoor et al., 2013). However, wet litter can sometimes be outside a grower’s control as in the case of several days of cool, damp, rainy weather. Wet litter has been recognized as a problem for almost 100 years (Dann, 1923), and is an issue of considerable economic and pathological importance (James and Wheeler, 1949). Unfortunately, as an industry, we have made little progress in resolving wet litter issues during the past 100 years.

Managing litter moisture is a continual process throughout the grow-out, not something to address only if litter gets wet. Moisture level at the surface of broiler litter is rarely measured, even though moisture at the litter surface should be considered important; however, average moisture of the entire litter depth is what we generally measure. If the surface is damp, manure caking occurs, slowing the rate of drying and movement of water into the litter below the caked surface (Dunlop and Stuetz, 2016).

What happens to manure after it is deposited on the litter surface depends on litter conditions, particularly moisture content, and management practices. If litter is near optimal moisture content of 25 percent (Collett, 2012), birds tend to work manure into the litter by scratching, dust bathing, and normal daily activity. If ventilation keeps litter loose and friable, wet manure is constantly mixed with drier litter particles, aiding the drying process. However, if litter can’t absorb all the moisture being applied, birds may be unable to mix fresh manure into the litter. This can happen when:

- litter has become matted or compacted,

- litter is too wet (>35-45 percent moisture content), or

- rate of manure deposition increases (disease, water quality issues, feed issues).

Caked litter, with its higher moisture content, reduces the birds’ ability to incorporate fresh manure into the litter and a wet layer forms on the litter’s surface. This highlights importance of litter management. Unless ventilation rate exceeds manure deposition rate, the caked layer will grow and remain wet. Wet litter is an animal welfare issue and puts the flock at risk of higher NH3 production, increased microbial and bacterial loads, footpad dermatitis, and other disease threats. If, however, deposition rate is less than evaporation rate, cake will begin to dry, and if evaporation remains greater than deposition over time, the entire caked layer may dry back out. Management is critical, however, and time is short to correct the problem so you must increase ventilation quickly if caked litter begins to form.

A host of multidimensional causal factors contribute to wet litter, including bedding material properties, litter conditions (friability, moisture content), bird activity, deposition rates, and ventilation program (Dunlop, 2017). In addition, litter is not homogeneous throughout its depth. The formation of cake results in a multi-layer mixture in the litter, with friable litter and caked layers having substantially different physical and chemical properties that can affect odor formation and emission (Miles et al., 2011). There are essential properties that all bedding materials should possess in order to avoid wet litter problems including having good water holding capacity and relatively quick drying times (Grimes et al., 2002). Dunlop (2017) developed an excellent list of key contributing factors and causes of wet litter and cake (List 1).

List 1. Key contributing factors and causes of wet litter and cake.1

- Moisture wicking from earthen floor; leaks in walls/roof/ceiling

- Drinker spillage (normal)

- Drinker spillage (issues)

- mismanagement, pressure, height, design

- Abnormal manure excretion

- disease, water quality, feed quality

- Stocking density

- Increased water excretion

- nutrition imbalance or ingredients, disease, increased water consumption, water quality, gut microbiota

- Increased in-house relative humidity

- exhaled moisture, wet litter, high ambient humidity, poor in-house temperature control

- Season

- winter is always a critical time for wet litter

- Condensation

- Lighting program

- light intensity (effect on bird activity), photoperiod

- Insufficient ventilation/air exchange

- in-house humidity build-up

- Farm biosecurity/cleaning practices

- Litter/bedding material type

- some materials are more absorbent than others

- Insufficient or excess litter depth

- 3-6” works best

- Cool/warm litter and cool/warm in-house air

- Litter moisture content/water holding capacity

1Adapted from Dunlop (2017).

Volume of water added to, evaporated from, and able to be stored in litter can contribute to occurrence of wet litter (Dunlop, 2017). Large quantities of water are added to litter by manure deposition and normal drinker spillage throughout a flock. Dunlop et al. (2015) estimated that the amount of water added to litter could be as much as 0.08 gal/ft² per day, with a cumulative total of over 2.45 gal/ft² during a 56-day grow-out. For a 25,000 sq. ft. house, that’s over 60,000 gals of water. This quantity of water tends to be manageable with today’s housing designs and proper ventilation management; however, avoiding wet litter may not be possible if additional water is added to litter because of disease status, drinking water quality issues, improper diet, use of certain feed ingredients, or if evaporation is reduced by extended periods of high outside humidity (Dunlop, 2017).

What this means to broiler growers is that litter management has never been more important than it is today. In addition, challenges to maintaining good litter quality have never been greater than they are today. No Antibiotics Ever (NAE) programs come with increased risks of coccidiosis and necrotic enteritis that can threaten litter quality. Litter quality is even more important to birds in NAE programs than to birds raised in conventional programs. Drinking water quality in NAE programs can create wet litter conditions if bacterial, mineral, and/or pH levels are outside acceptable ranges. Adequate ventilation rates (particularly during winter) are critical to maintain evaporation and ensure that litter stays loose and friable.

Don’t be afraid to burn a little fuel to save litter quality. As a rule, increasing air temperature by 20° F doubles the moisture-holding capacity of air. This is what allows moisture removal from the broiler house. We bring in relatively cool, dry air from outside, heat it up so that it holds more moisture than it did when it entered the house and then remove this moisture-laden air with minimum ventilation. If fan run-time settings are adequate for bird age, moisture build-up should not occur, because more moisture-laden air is being exhausted than pulled in. If settings are inadequate, moisture levels may continue to build in the house until litter becomes saturated and begins to slick over and form cake.

Recycling broiler litter to grow multiple flocks is a common practice that has both benefits and challenges. If litter can be kept dry, paw quality is generally better on recycled litter than on new bedding. Reusing litter can also save money by preventing or delaying the expense of purchasing new bedding material if/when the houses are cleaned out. Litter treatments can be used to help manage ammonia levels during the brood period of a flock. However, recycling litter is not without challenges. There is greater potential for high ammonia levels with built up litter vs. new bedding material. Odor and moisture issues are also a concern. Ammonia is a serious animal welfare and economic threat to the poultry industry and must be managed as such.

Litter treatments are acidifiers, and growers should follow manufacturers’ recommendations, guidelines and precautions for their safe use and handling. Although, most of the challenges can be overcome, and the advantages of recycling litter tend to outweigh the disadvantages.

References

Bilgili, S. F., J. B. Hess, J. P. Blake, K. S. Macklin, B. Saenmahayak, and J. L. Sibley. 2009. Influence of bedding materials on footpad dermatitis in broiler chickens. J. Appl. Poult. Res.8:345-351.

Collett, S. R. 2012. Nutrition and wet litter problems in poultry. Anim. Feed Sci. Tech. 173:65-75.

Dann, A. B. 1923. Wet litter in the poultry house. Poult. Sci. 3:15-19.

Dunlop, M. W., P. J. Blackwell, and R. M. Stuetz. 2015. Water addition, evaporation, and water holding capacity of poultry litter. Sci. Total Environ. 538:979-985.

Dunlop, M. W., and R. M. Stuetz. 2016. Wet litter – Factors associated with the shed environment and litter properties. 27th Annual Australian Poultry Science Symposium. Sydney, New South Wales. 14th-17th February 2016. Available at: https://az659834.vo.msecnd.net/eventsairaueprod/production-usyd-public/34779a9ed4af49c8962ac333680a9ed1. Accessed: May 7, 2021.

Dunlop, M. W., P. J. Blackall, and R. M. Stuetz. 2016a. Odour emissions from poultry litter – A review litter properties, odour formation and odorant emissions from porous materials. J. Env. Mgmt. 177:306-319.

Dunlop, M. W., A. F. Moss, P. J. Groves, S. J. Wilkinson, R. M. Stuetz, and P. H. Selle. 2016b. The multidimensional causal factors of “wet litter” in chicken-meat production. Sci. Total Environ. 562:766-776.

Dunlop, M. W. 2017. Quantifying poultry litter conditions and relationships with odour emissions. Ph.D. Thesis. University of New South Wales, Australia.

Elliott, H. A., and N. E. Collins. 1982. Factors affecting ammonia release in broiler houses. Trans ASAE. 25(2):413-418.

Gates, R. S., J. L. Taraba, N. S. Ferguson, and L. W. Turner. 1997. A technique for determining ammonia equilibrium and volatilization from broiler litter. Paper. No. 974074. In: ASAE Ann. Int. Meet. Minneapolis, MN. ASAE. St. Joseph, MI.

Grimes, J. L., J. Smith, and C. M. Williams. 2002. Some alternative litter materials used for growing broilers and turkeys. World’s Poult. Sci. J. 58:518-526.

James, E. C., and R. S. Wheeler. 1949. Relation of dietary protein content to water intake, water elimination, and amount of cloacal excreta produced by growing chickens. Poult. Sci. 28:465-467.

Mackie, R. I., P. G. Stroot, and V. H. Varel. 1998. Biochemical identification and biological origin in key odor components in livestock waste. J. Anim. Sci. 76:1313-1342.

Miles, D. M., D. E. Rowe, and P. R. Owens. 2008. Winter broiler litter gases and nitrogen compounds: Temporal and spatial trends. Atmos. Environ. 42:3351-3363.

Miles, D. M., J. P. Brooks, and K. R. Sistani. 2011. Spatial contrasts and seasonal and interflock broiler litter trace gas emissions, physical and chemical properties. J. Environ. Qual. 40:176-187.

Pillai, S. M., G. Parcsi, X. Wang, and R. M. Stuetz. 2012. Odour abatement of poultry litter using odour control products. Chem. Eng. Trans. 30:247-252.

Shepherd, E. M., and B. D. Fairchild. 2010. Footpad dermatitis in poultry. Poult. Sci. 89:2043-2051.

Tabler, T., J. Wells, and W. Zhai. 2012. Managing litter moisture in broiler houses with built-up litter. Mississippi State University Extension Service. Publ. No. 2744. November.

Trabue, S., K. D. Scoggin, H. Li, R. Burns, H. Xin, and J. Hatfield. 2010. Speciation of volatile organic compounds from poultry production. Atmos. Environ. 44:3538-3546.

van der Hoeven-Hangoor, E., N. D. Paton, I. B. van de Linde, M. W. A. Verstegen, and W. H. Hendriks. 2013. Moisture content in broiler excreta is influenced by excreta nutrient contents. J. Anim. Sci. 91(12):5705-5713.

Wadud, S., A. Michaelsen, E. Gallagher, G. Parcsi, O. Zemb, R. Stuetz, and M. Manefield. 2012. Bacterial and fungal community composition over time in chicken litter with high or low moisture content. Br. Poult. Sci. 53:561-569.

Woodbury, B. L., J. E. Gilley, D. B. Parker, D. B. Marx, and R. A. Eigenberg. 2015. VOC emissions from beef feedlot pen surfaces as affected by within-pen location, moisture, and temperature. Biosyst. Eng. 134:31-41.

Xin, H., I. L. Berry, and G. T. Tabler. 1996. Minimum ventilation requirement and associated energy cost for aerial ammonia control in broiler houses. Trans. ASAE. 39(2):645-648.